“Concern about toxic gases escaping from Southern calif gas storage facility due to faults and fissures inherent in the geology of the area and the lack of adequate gas monitoring. Kew (1929) and Hansen (1984) describe a geologic area riddled with faults that make gas excaping a certainty. The oils wells that were there previously contain toxic materials, including benzene (a known carcinogen) and other petroleum products that, mixed with natural gas, pose a Hazzard should they escape. Placement of gas monitors has not been shown to coincide with known faults nor has gas analysis been done periodically to show the gases do not contain hazardous materials. All these concerns should be monitored.”

SAFETY OMBUDSMAN RESPONSE: There are basically four issues embedded within this concern including:

Issue 1) The concern that Kew, in 1929, characterized the geologic region as riddled with faults that make gas escaping from the storage field a certainty;

Issue 2) The oils that were previously native to the storage reservoir contain toxic materials including benzene and other petroleum products that when mixed with natural gas pose a hazard in the event they escape from the storage formation;

Issue 3) Placement of gas monitors has not been shown to coincide with known faults; and,

Issue 4) Gas analysis has not been done periodically to show the gases do not contain hazardous materials.

Each issue is addressed separately below.

Issue 1 – The Geologic Region is Riddled with Faults That Make Gas Escaping from the Storage Field A Certainty

The paper authored by Kew in 1929 discusses the general nature of the geologic region surrounding the Aliso Canyon Facility, including the existence of several faults, and specifically the Santa Susanna fault. Kew also mentions the existence of a number of hydrocarbon seeps that were discovered in the area, though given the complexity of the local geology there is no practical means of linking those seeps to a particular hydrocarbon reservoir, including the reservoir used by SoCalGas for gas storage purposes.

The storage formation operated by SoCalGas exists between approximately 7,000 and 10,000 feet below the surface. There are multiple porous and permeable formations at shallower depths, some of which also contain hydrocarbons, and some of which may also still be under production by third parties other than SoCalGas. Thus, as noted above, there is no way of determining the actual source of the hydrocarbon seeps mentioned by Kew. The natural hydrocarbon seeps could very well have been associated with one or more of the shallower hydrocarbon-bearing formations or a deeper formation below the zone used by SoCalGas for its operations.

Pursuant to DOGGR Order No. 1118, dated July 19, 2017, SoCalGas was required to, among other things, perform a seismic risk study including a comprehensive assessment of the geotechnical hazards present at the Aliso Canyon Facility. SoCalGas assembled a team of renowned independent experts to examine these hazards and their associated risks. Where the paper authored by Kew discusses the geologic complexity on a more regional basis, the studies performed pursuant to DOGGR Order No. 1118 examine the geotechnical hazards specific to the Aliso Canyon Facility. As such, the reports discussed below provide a much more comprehensive and up to date assessment of geotechnical risks associated with the storage facility.

A total of ten hazard assessments were completed which examined the wells at the facility and the facility’s geology. The reports are numbered 1-10 and address hazards associated with:

Report 1 Landslide Hazard Report;

Reports 2 & 3 Stability Analysis of Landslide-prone Slopes and Wellbore Landslide Loading Assessment;

Report 4 Geologic and Geomechanical Study;

Report 5 Probabilistic Seismic Hazard Analysis;

Report 6 Probabilistic Fault Displacement Hazard Analysis;

Reports 7 & 8 Wellbore Loading Assessment and Shear Testing and Finite Element Analysis of 1:10 Scale Pipe Samples;

Report 9 Well Flow Modeling; and

Report 10 Dynamic Gas Flow Analysis

Collectively, these reports assess the hazards and associated risks due to ground motion and fault displacement, subsurface leaks due to well casing failure resulting from displacement and, potential gas flow rates and volumes through geologic structures and wells, all as a result of earthquake induced damage.

The proposed scope of work for each of these assessments was reviewed by the California Department of Conservation, Geologic Energy Management Division (CalGEM, formerly DOGGR) and independent technical experts from Lawrence Berkley, Lawrence Livermore, and Sandia National Laboratories (the National Labs), whose feedback was used to extend and improve the technical assessments. Collectively, these assessments and the reports associated with each speak extensively to the geologic complexity of the region in which the Aliso Canyon Facility exists, and the potential geologic, seismologic, and geomechanical risks associated with the facility. Overall, the studies indicate that seismic risks at the Aliso Canyon Facility are relatively low and can be reasonably managed and/or mitigated.

An overview of the entire study, a draft summary of the results of each report, and a draft of the entirety of each of the ten individual reports may be accessed by clicking this link. The draft reports were submitted to DOGGR and the National Labs for review and comment in March 2019.

Issue 2 – Oils Native to The Storage Reservoir Contain Toxic Materials Including Benzene and Other Petroleum Products That When Mixed with Natural Gas Pose a Hazard in The Event They Escape from The Storage Formation.

Natural gas itself is considered a hazardous material by the federal government as well as the State of California. It may indeed pose a hazard if it escapes from surface piping or the Aliso Canyon gas storage reservoir and migrates to the surface or to shallower aquifer systems; the same is true for natural gas leaks in general irrespective of the leak source. That said, natural gas associated with SoCalGas’ storage operations is normally contained and, as such, does not pose an unacceptable level of risk so long as it remains contained. SoCalGas is subject to strict new State and Federal safety regulations that were implemented in large part due to the Aliso Canyon incident. These new state and federal regulations require SoCalGas to develop a program for managing risks associated with their storage operations, including risks associated with gas leakage, and to perform comprehensive storage well integrity demonstration, verification, and monitoring. They also impose immediate reporting obligations for gas leaks and routine periodic reporting obligations related to facility integrity, which together provide a comprehensive framework to help ensure against future leaks from the facility. A PDF copy of the State of California Department of Conservation, Geologic Energy Management Division (CalGEM) underground gas storage regulations may be accessed by clicking this link.

A copy of the US Department of Transportation’s Pipeline and Hazardous Materials Safety Administration’s (PHMSA) Interim Final Rules related to underground gas storage may be accessed by clicking this link.

Issue 3 – Placement of gas monitors has not been shown to coincide with known faults

There are eight fence-line methane monitoring stations (sensors) at the Aliso Canyon Facility. SoCalGas investigated several potential sites to place the methane sensors to ensure optimal detection of methane while minimizing the impact to the community as much as possible. The criteria for site selection was primarily based on the geographic terrain, environmental factors, equipment accessibility, proximity to residential neighborhoods and likely dispersion of any gas leaks. Known faults were not considered in determining the placement of the fence-line methane monitors as the system would not be significantly impacted by the location of such faults.

The location of the monitors can be viewed by clicking on this link.

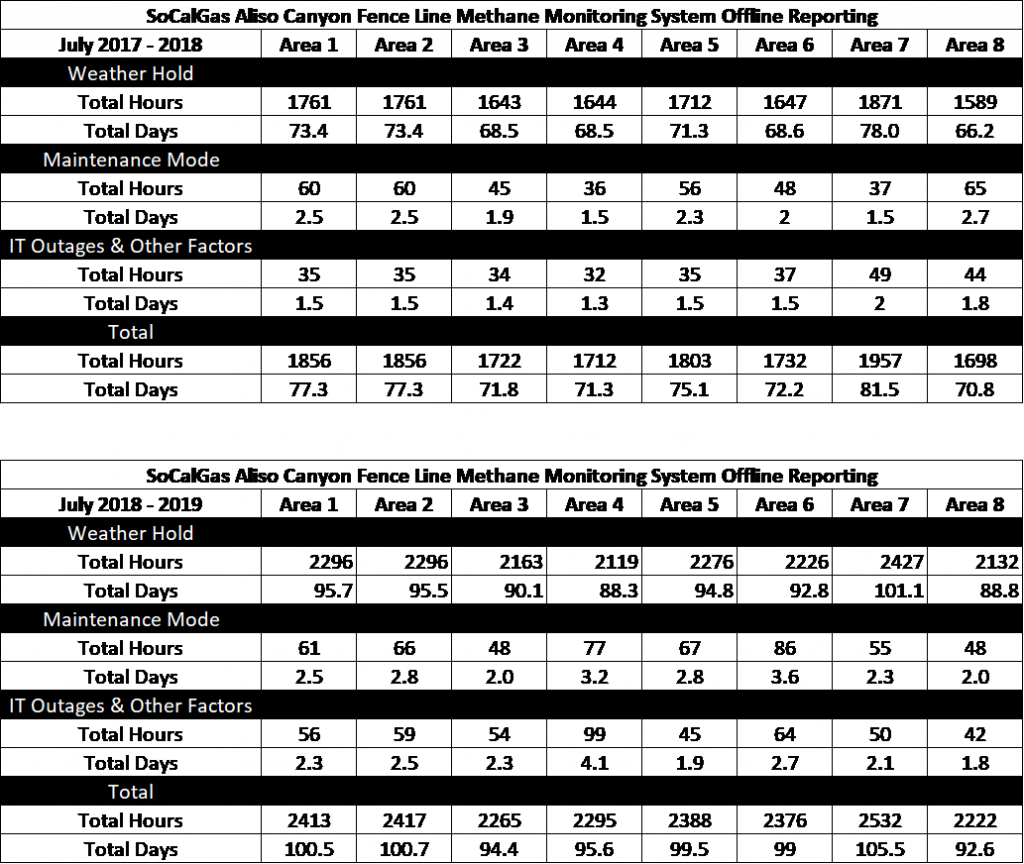

A data request was submitted to SoCalGas requesting information concerning the on-line versus off-line status of the fence-line methane sensors. The request covered the period coincident with the activation of the sensors (July 2017) through July 2019. SoCalGas tracks and records the reliability of its fence-line methane monitoring stations – i.e. the number of hours or days when each station is on-line and actively monitoring methane emissions versus off-line due to maintenance and/or repair. They categorize the off-line periods according to the nature of the causative factors. The Fence-Line Methane Monitoring System is offline when there is a “Weather Hold,” a “Beam Block Mode”, when “Maintenance Mode” is enabled, or when there is an “IT Outage or Outage Due to Other Factors”. Table 1 below provides a summary of the off-line hours covering the two-year period from July 2017 – July 2019.

It is important to note that “Total Days” as referenced for each of the eight area sensors listed in the tables below is a mathematical calculation based on the “Total Hours”; “Total Days” are equal to “Total Hours” divided by 24. Thus, the figures listed in Table 1 do not necessarily reflect that a sensor was off-line for a continuous 24-hour period during any given day. For example, early morning fog could result in a sensor being off-line for a period of hours. When fog dissipates and relative humidity falls below the 80 percent threshold, the sensors are designed to automatically resume on-line status and recording of methane concentrations.

Table 1

“Weather Hold” automatically occurs when relative humidity levels are 80% or greater consistent with the manufacturers’ general recommendation. Humidity levels above 80% may result in false readings caused by the interference of humidity in the open path of the infrared detectors. For a Weather Hold to be disabled, humidity must remain below 80% for 10 minutes.

“Maintenance Mode” is enabled by the Storage Operations Room personnel to allow for instrument technicians to perform repairs or calibrations. “0 PPM” values are displayed while Maintenance Mode is enabled.

“IT Outage & Other Factors” refers to when IT maintenance is performed on the server or unplanned outages occur due to various disconnection reasons. Examples of IT outages include such things as temporary network loss, monitors being reset, servers being reset, and IT maintenance mode.

“Beam Block Mode” automatically occurs when beam block levels are 50% or greater. For a “Beam Block Mode” to be disabled, beam block levels must remain below 50% for 10 minutes. “Beam Block” is interference with the fence line monitor infrared signal commonly caused by fog.

In the event of an outage due to Weather Hold, Beam Block Mode, or Maintenance Mode which persists for a period of six hours or greater, Storage Operations personnel conduct field surveys using portable methane detectors to verify methane concentrations. If the outage extends for 12 hours or greater the manual surveys are conducted every six hours thereafter until the problem which caused the outage is corrected. Manual readings are not posted on the Fence line Monitoring website.

It is noteworthy that Areas 1 and 2 share a common relative humidity sensor as do Areas 3 and 4. The total offline hours for all monitors will be different based on which offline event is active. When multiple offline events occur simultaneously, not all will be recorded. For example, if a monitor has a Weather Hold triggered, but goes offline during the Weather Hold due to a Maintenance Mode or IT/Other Factor outage, the offline mode other than Weather Hold will be recorded. This will lead to shared sensors for Areas 1 and 2 and Areas 3 and 4 to record different total Weather Hold hours.

Table 1 above provides a summary of the off-line status of each of the eight methane sensor stations from the time they were first placed into service in July 2017 through July 2019. During the period of July 2017 – July 2018 the eight sensors were off-line an average of 1792 hours each (the equivalent of about 75 days), or approximately 20 percent of the time. Approximately 95 percent of the off-line time (an average of about 1704 hours for each sensor) was reportedly due to “Weather Hold” status when relative humidity exceeded 80 percent. Off-line time due to “Maintenance Mode” and “IT Outages & Other Factors” accounted for only 51 hours and 38 hours, respectively, or about one percent combined. During the period of July 2018 – July 2019, the eight sensors were each off-line an average of 2364 hours, or approximately 27 percent of the time. Like the year prior, most of the off-line time (an average of 2242 hours for each sensor) was reportedly due to “Weather Hold” status. Off-line time due to “Maintenance Mode” and “IT Outages & Other Factors” accounted for an average of only 64 hours and 60 hours, respectively. Combined, this again amounts to a little over one percent of the operating time. These figures strongly suggest that relative humidity levels above 80 percent, which are clearly weather related, were responsible for most of the system off-line time since the methane monitoring sensors were installed. Routine maintenance and other factors resulted in the system being off-line approximately one percent of the operating time since installation of the system, which appears to be within reason from a reliability perspective.

A supplemental data request was made to SoCalGas for a listing of each day (or partial day) when the methane monitoring sensors were off-line due to “Weather Hold” status, or relative humidity above 80 percent. The purpose of this request was to confirm whether all eight of the sensors were detecting relative humidity levels above 80 percent during the same periods (days or partial days), recognizing that the sensors are in fairly close proximity to one another. While acknowledging that local terrain/topography can have some impact, one would expect relative humidity readings to be uniform across a small regional area such as the area within which the fence line methane monitoring system exists. SoCalGas provided the requested information, and that information is summarized in Table 2, which can be found here.

The data in Table 2 illustrate that all eight sensors were off-line 81 percent of the time when any of the sensors (one or more) was off-line due to relative humidity levels above 80 percent. In other words, in eight out of ten instances, if one of the sensors went off-line due to relative humidity above 80 percent, the remaining sensors detected the same condition and went to off-line status as well. Given the localized terrain, it’s conceivable that small, highly localized fog conditions could trigger an off-line condition at a single sensor while relative humidity conditions at the next nearest sensor remains slightly below the 80 percent relative humidity threshold. Thus, the off-line status correlation between all eight sensors appears reasonable, particularly given the local terrain/topography in which the sensors are located.

In summary, since placing the methane monitoring sensors into service in 2017, most of the off-line time associated with the system is attributable to weather related conditions and not a failure of the system per se. Actual off-line time due to maintenance and IT issues amounts to the equivalent of approximately 4-5 days per year or a little over one percent of the time, which appears within reason.

Issue 4 – Gas analysis has not been done periodically to show the gases do not contain hazardous materials

As noted above in response to Issue 2, natural gas itself is considered a hazardous material. SoCalGas has a written standard which outlines the requirements for obtaining compositional analysis of gas samples from its underground storage facilities, including the Aliso Canyon facility. The written standard has been in place since October 2017, however periodic gas sampling from Aliso Canyon has taken place since the 1970’s. Generally speaking, SoCalGas’ gas sampling standard indicates they conduct gas sampling and analysis on select wells at their storage facilities on a scheduled basis and on an ad-hoc basis to determine the gas composition for purposes of monitoring for evidence of gas migration, gas leakage, corrosivity, and for purposes of verifying stored gas inventory. When gas is withdrawn from the Aliso Canyon facility, it is processed and analyzed for C1-C6+, CO2, and air, and this information is used for analysis to determine gas heating value and calculate the WOBBE index of the gas. The scope of this analysis (the target hydrocarbon and inert components referenced above) is generally consistent with gas storage industry practice in determining the chemical composition of stored gas for use in measurement calculations and storage gas inventory verification. It is also consistent with SoCalGas’ internal gas standards noted below. An analysis of the gas injected into the storage reservoir is submitted to the California Department of Conservation, Geologic Energy Management Division (CalGEM) on an annual basis.

SoCalGas also has a gas standard which specifies the testing of gas samples to determine proper gas quality, heating value, and for pipeline integrity. This standard applies to supplier gas entering the SoCalGas system. Prior to flowing gas into the SoCalGas system, 24-hour testing is conducted at a supplier custody transfer point to ensure the gas complies with SoCalGas’ gas quality requirements. This testing is not performed on gas being injected into the Aliso Canyon facility since the gas has already been tested upstream of the storage facility.